Sound has been an essential part of human life since time immemorial. It has played a crucial role in communication, entertainment, and even in advanced technologies like sonar and ultrasound. One of the exciting developments in sound technology is the concept of acoustic levitation, a physical phenomenon that uses the power of sound waves to levitate objects in the air. But, is it possible that acoustic levitation could open up new methods for material handling in the manufacturing industry? In this article, we explore this fascinating concept and its potential future applications.

Understanding Acoustic Levitation

Before delving into the potential applications in manufacturing, it’s essential to understand what acoustic levitation is and how it works. Acoustic levitation involves the use of sound waves to lift and suspend objects in mid-air.

Also read : Can Advanced Prefabrication Methods Streamline Sustainable Housing Development?

What is Acoustic Levitation?

Acoustic levitation is a method of suspending matter in a medium by using acoustic radiation pressure from intense sound waves. Sound waves are pressure waves; when they pass through air, they create areas of compression and rarefaction. By carefully controlling the acoustic field, objects can be levitated and manipulated without any physical contact.

If you’re interested in more scholarly articles on this topic, Pubmed and Google Scholar are great resources to explore. They house a wealth of research papers and studies on acoustic levitation and its potential applications.

Also to discover : How Might AI-Enhanced Satellite Imaging Predict Environmental Changes?

How Does it Work?

The mechanism behind acoustic levitation is the phenomenon of resonance and the formation of standing waves. When sound waves of the correct frequency are aimed at a reflecting surface, they bounce back and create areas of constructive and destructive interference. These areas form a standing wave pattern, where specific points, known as nodes, are points of minimum vibration.

An object placed at a node will experience an upward force counteracting gravity, effectively allowing it to levitate. This can be achieved using a device known as an acoustic levitator, which creates and controls the sound field necessary for levitation.

The Components of Acoustic Levitation System

An acoustic levitation system comprises of the sound source, the levitation chamber, the object to be levitated, and often, a means of monitoring or measuring the levitated object.

The Sound Source

The sound source, also known as the transducer, is what generates the sound waves used in acoustic levitation. Usually, these sound sources operate at ultrasonic frequencies, which are above the range of human hearing. The frequency of the sound source needs to be meticulously controlled, as it directly impacts the size and the number of objects you can levitate.

The Levitation Chamber

The levitation chamber is the space where the levitation takes place. It consists of a reflecting surface and a source of sound waves. By adjusting the distance between the source and the reflector, you can create a standing wave pattern within the chamber.

The Levitated Objects

The levitated objects can be solid particles, liquid droplets, or even small living organisms. The size, density, and composition of these objects will influence their behavior in the acoustic field.

Data Monitoring and Collection

In many applications of acoustic levitation, it’s important to closely monitor the levitated objects and collect data about their behavior. This might involve cameras, temperature sensors, or even more specialized equipment, depending on the application.

Potential Applications in Manufacturing

Now that we’ve covered the basics of acoustic levitation, let’s explore its possible applications in the manufacturing sector.

Material Handling and Processing

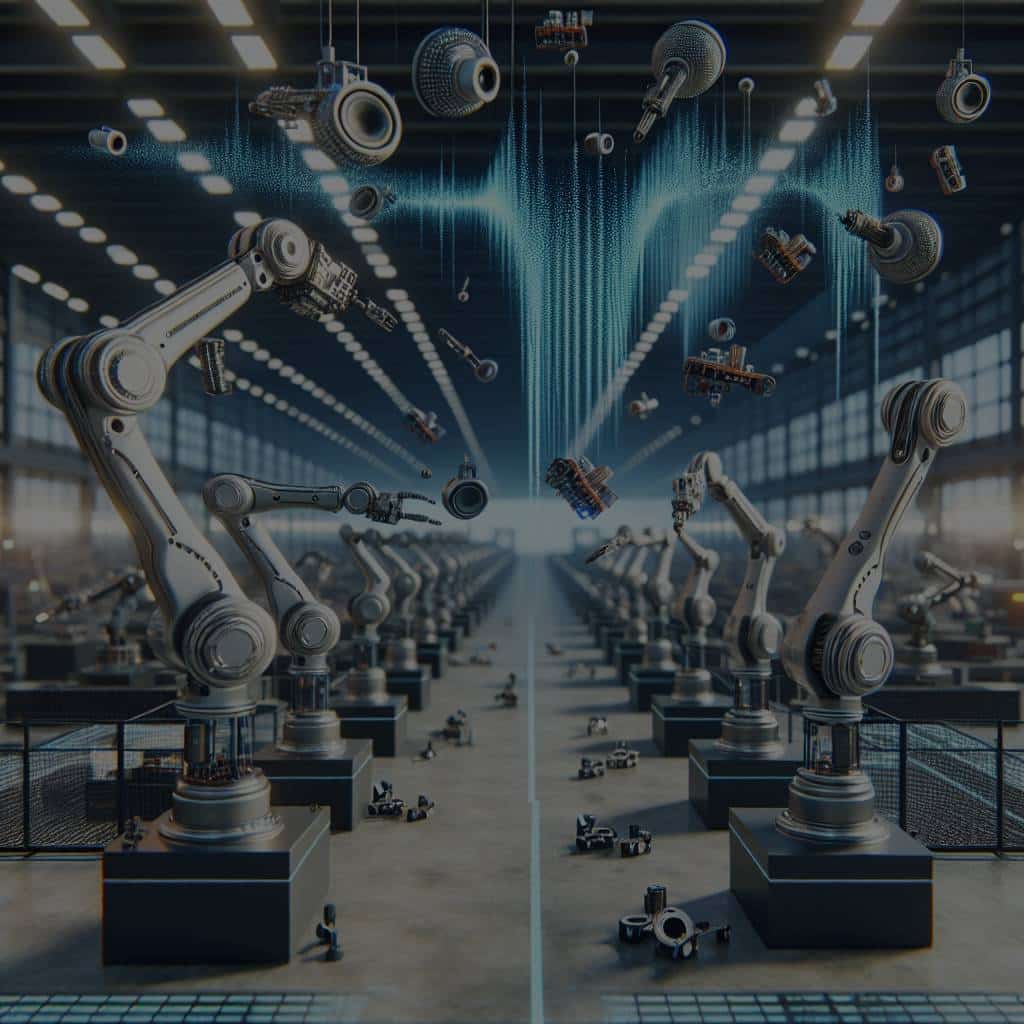

Imagine a method of handling materials that doesn’t involve any physical contact. This could be particularly useful for handling delicate, high-value items that could be damaged by conventional handling methods.

Creating Novel Materials

Another exciting possibility is the creation of novel materials. By levitating and manipulating materials acoustically, it might be possible to arrange atoms or molecules in ways that aren’t achievable under normal gravitational conditions.

Improved Quality Control

Acoustic levitation could also offer new ways to inspect and test products. For example, levitating a product and examining it from all angles could make it easier to spot defects.

Challenges and Future Development

Despite its potential, many challenges must be overcome before we see acoustic levitation widely adopted in the manufacturing industry.

Limitations of Current Technology

Current acoustic levitation technology has limitations. For instance, it requires a precise setup and can only levitate relatively small objects. However, advancements in technology and a better understanding of the underlying principles could help overcome these challenges.

Safety Considerations

Safety is another critical factor. High-intensity sound waves can be harmful to human health, so any industrial application of acoustic levitation would need to ensure the safety of workers.

Despite these challenges, the potential benefits of acoustic levitation in manufacturing are significant. As research progresses and technology advances, acoustic levitation might become a common feature in factories of the future. So, keep your ears open – the sounds of the future might just be levitating!

Acoustic Levitation: Current Research and Advances

In recent years, acoustic levitation has been the subject of extensive research, both in the field of academia and in applied technology. Google Scholar, a widely accessed database of academic literature, lists numerous studies dedicated to the various aspects of acoustic levitation, ranging from the fundamental physics involved to its potential applications in different fields.

Advancements in Acoustic Levitation Technology

One key area of focus has been increasing the size and weight of the objects that can be levitated. The development of more advanced acoustic levitators, utilizing sophisticated sound sources and manipulating the acoustic field with increased precision, has seen significant strides in this direction. For example, researchers have successfully levitated heavier and larger objects by optimizing the frequency of the sound waves and the configuration of the sound field.

Additionally, researchers are exploring new methods of manipulating levitated objects. A relatively new phenomenon, known as acoustic streaming, has been harnessed to rotate and translate levitated objects in the sound field. This adds a new dimension of control, paving the way for more complex operations and handling of materials.

Acoustic Levitation in Containerless Processing

Another active area of research is containerless processing, a technique that involves levitating a material in mid-air while it undergoes a process such as melting, cooling, or even chemical reactions. This technique could allow for the creation of unique materials that cannot be produced under normal conditions because containers can interfere with the processing or contaminate the final product.

For example, in the United States, researchers have used acoustic levitation to create a unique type of glass by levitating and cooling molten droplets. This method could provide a new approach to creating high-purity materials, especially in industries such as pharmaceuticals and semiconductors.

Conclusion: The Future of Acoustic Levitation in Manufacturing

The journey of acoustic levitation from a fascinating scientific concept to a potential game-changer in manufacturing is undoubtedly exciting. Although the technology is still in its early stages, its potential applications suggest that it could revolutionize the way we handle and process materials in the future.

While current limitations, such as the size of levitated objects and safety considerations, need to be addressed, advances in technology and ongoing research are propelling us closer to a future where acoustic levitation is commonplace in the manufacturing industry.

Moreover, the ability to manipulate levitated objects using acoustic waves could lead to the creation of novel materials and improved quality control methods. Indeed, the application of acoustic levitation could bring about unprecedented precision and flexibility in manufacturing processes.

In conclusion, while there are challenges to surmount, the potential of acoustic levitation in manufacturing is immense. As researchers continue to unlock the mysteries of acoustic radiation and sound fields, and as engineers develop more advanced acoustic levitators and transducers, the day when we see levitated objects in production lines might not be far off.

So, as we step into the future, we may quite literally hear the hum of progress – the low, resonant hum of sound waves levitating and moving objects with unprecedented precision. The future of manufacturing might just be floating in mid-air!